The 60th foundation was rammed in the Hohe See wind farm on Friday

In this construction project, the Big Bubble Barrier is used in duplicate 88 times. An enormous underwater noise is generated during the ramming phase, held back by the Big Bubble Barrier system up to 95%. The team from Hydrotechnik Lübeck on the deck of the Nozzle Hose Deployment Vessel is proud that the noise reduction values have so far been complied with at all ramming positions. Not least, thanks to constant optimization in practice.

Big Bubble Barrier soundproofing with 22 compressors

The Blue Aries was specially converted for this use. The hose winches of the Big Bubble Curtain with 22 powerful compressors are permanently installed on deck. Everything is welded securely by regulations. The latest technology is used to navigate when the nozzle hoses are deployed. The nozzle hose’s exact position is checked afterward using GP2 (Dynamic Positioning 2) and GPS.

497 MW from 2019

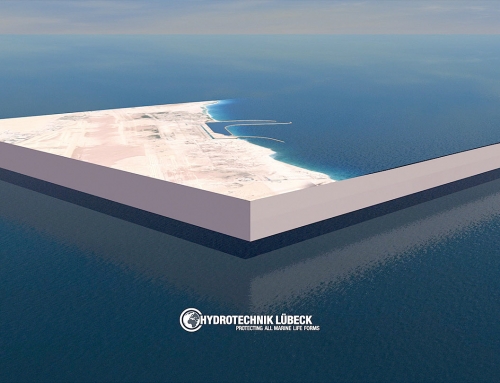

The Hohe See wind farm is being built very far out in the North Sea. It is located around 100 kilometers northwest of Helgoland. From 2019 the wind farm will produce 497 MW over an area of around 53 square kilometers.